How does Stainihard® work?

More than 1200 hardness vickers, without having a negative impact on corrosion resistance.

Read more about how it works in the white paper:

Depending on your application, there are different process options, with the goal of achieving the desired properties.

During the Stainihard® process the surface will be enriched with nitrogen and carbon in a special way. With austenitic stainless steel this is not in a more regular way possible. Nitrogen and carbon diffuse into the product surface at a low temperature (<450°C). The result is a very high surface hardness (1200-1400HV0.05) without negatively affecting the corrosion resistance!

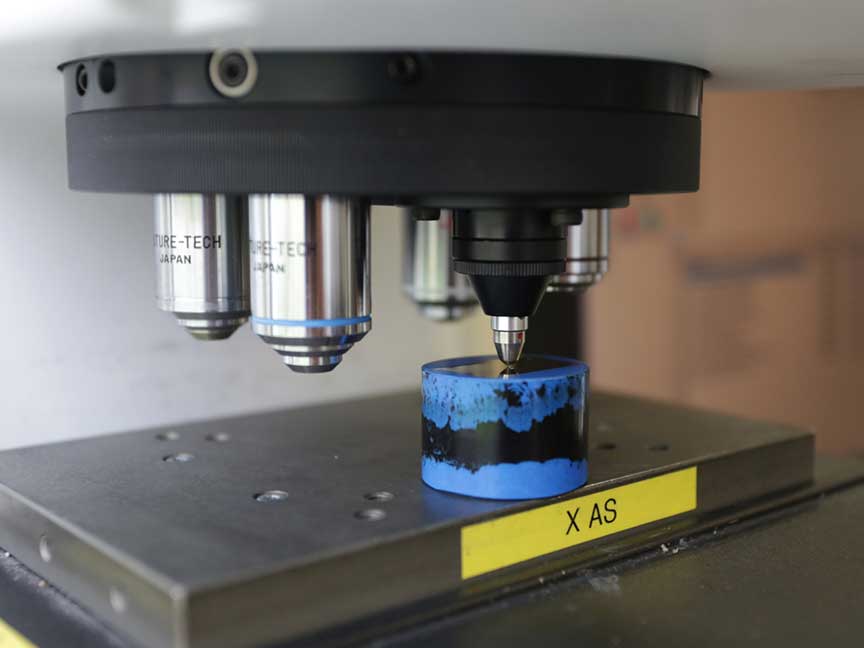

composition and structure

The Stainihard® layer is an expanded austenite zone (also called s-phase). This zone consists of the stainless steel material in question containing an oversaturation of nitrogen and carbon atoms. This supersaturation causes high compressive stresses. As a result, the hardness increases significantly, without having a negative impact on the corrosion resistance. The reason is that with Stainihard® NC the formation of chromium nitride (CrN) and/or chromium carbide (CrC) is suppressed (creation of the expanded austenite). This in contradiction to the classical nitration processes, such as salt bath and plasma nitration, where the formation of chromium nitride and chromium carbide results in a significant loss of corrosion resistance!

The depth of this expanded austenite zone formed at Stainihard depends on the chosen stainless steel material, the degree of deformation as well as the surface condition of the material.