How does Stainihard® work?

More than 1200 hardness vickers, without having a negative impact on corrosion resistance.

Read more about how it works in the white paper:

The process

Stainihard® NC is a special process used to harden the surface of austenitic and duplex stainless steel (RVS) without compromising its corrosion resistance (resistance to rust). In some cases, corrosion resistance is even improved!

How does it work?

The process is based on gas nitrocarburising, but specially adapted for stainless steel.

During the Stainihard® process, the surface of the steel is enriched with nitrogen and carbon atoms.

This diffusion takes place at a low temperature (below 450°C).

The result: a very hard outer layer (1100–1400 HV0.05) without loss of corrosion resistance.

The hardened zone is also called “expanded austenite” or “S-phase.” Here, the extra nitrogen and carbon atoms are trapped, creating high compressive stresses and thus higher hardness.

Unlike classical processes (such as salt bath or plasma nitriding), Stainihard® does not form chromium nitrides or carbides, so corrosion resistance is maintained.

Stainihard is not a coating and is therefore safe for use in the food and medical industries.

Advantages of Stainihard®

- Very high surface hardness

- Excellent wear resistance (protection against abrasion)

- High resistance to galling, seizing, and contact corrosion

- Corrosion resistance is maintained

- High resistance to shearing

- No visible change to the surface

- Lower coefficient of friction

- Higher fatigue strength

- Good dimensional and shape stability

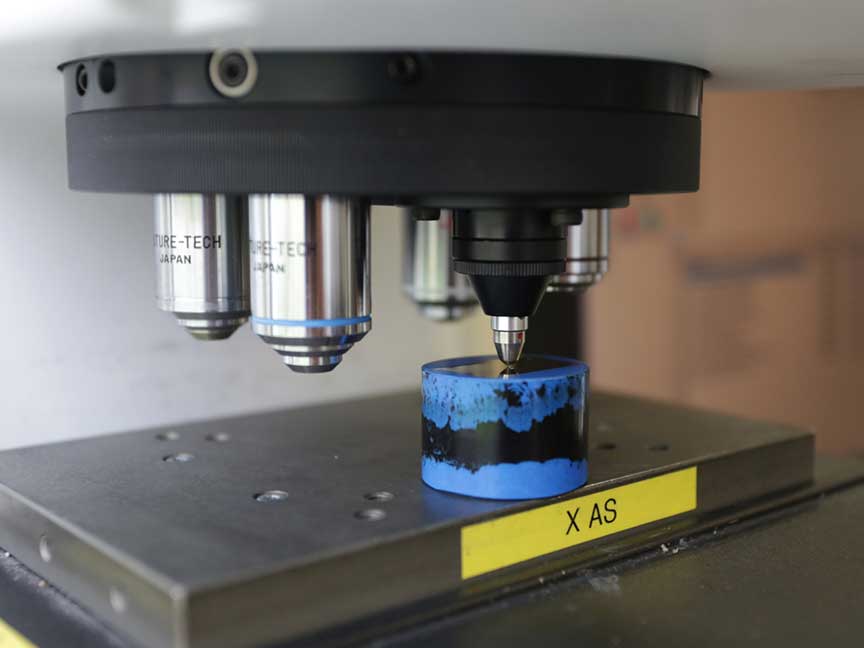

Hardness and depth

The hardness of the Stainihard® layer is 1200–1500 HV0.01.

The hardening depth varies from 10 to 30 µm, depending on the type of stainless steel, surface condition, and degree of deformation.

Applications

Stainihard® NC is suitable for hardening the surface of austenitic and duplex stainless steel. It is used for products that require extra wear resistance and hardness, without sacrificing corrosion resistance.

Want to know more about applications?

Technical explanation

The Stainihard® layer is an “expanded austenite zone” (also known as the S-phase) that forms through the diffusion of nitrogen and carbon atoms into the surface of austenitic stainless steel (RVS). During the Stainihard® NC process, these atoms are introduced in excess into the crystal lattice of the stainless steel, resulting in significant compressive stresses. This leads to a substantial increase in surface hardness, without compromising the corrosion resistance of the base material.

What makes the Stainihard® process unique is that the formation of chromium nitride (CrN) and chromium carbide (CrC) is suppressed. As a result, the chromium remains dissolved in the matrix, which is essential for maintaining the passive layer and thus the corrosion resistance. This distinguishes Stainihard® from conventional nitriding processes such as salt bath or plasma nitriding, where the formation of CrN and CrC does occur and corrosion resistance is greatly reduced.

The depth of the formed expanded austenite zone depends on several parameters:

- The chemical composition of the chosen stainless steel type (for example, the nickel and chromium content)

- The degree of prior plastic deformation of the material

- The surface condition (roughness, cleanliness)

These factors influence the diffusion rate of nitrogen and carbon, and thus the final layer thickness and properties of the Stainihard® treatment.